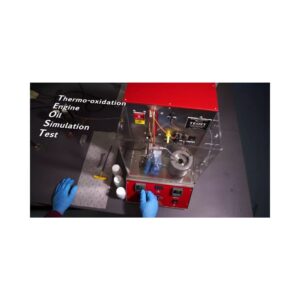

Thermo-Oxidation Engine Oil Simulation Test

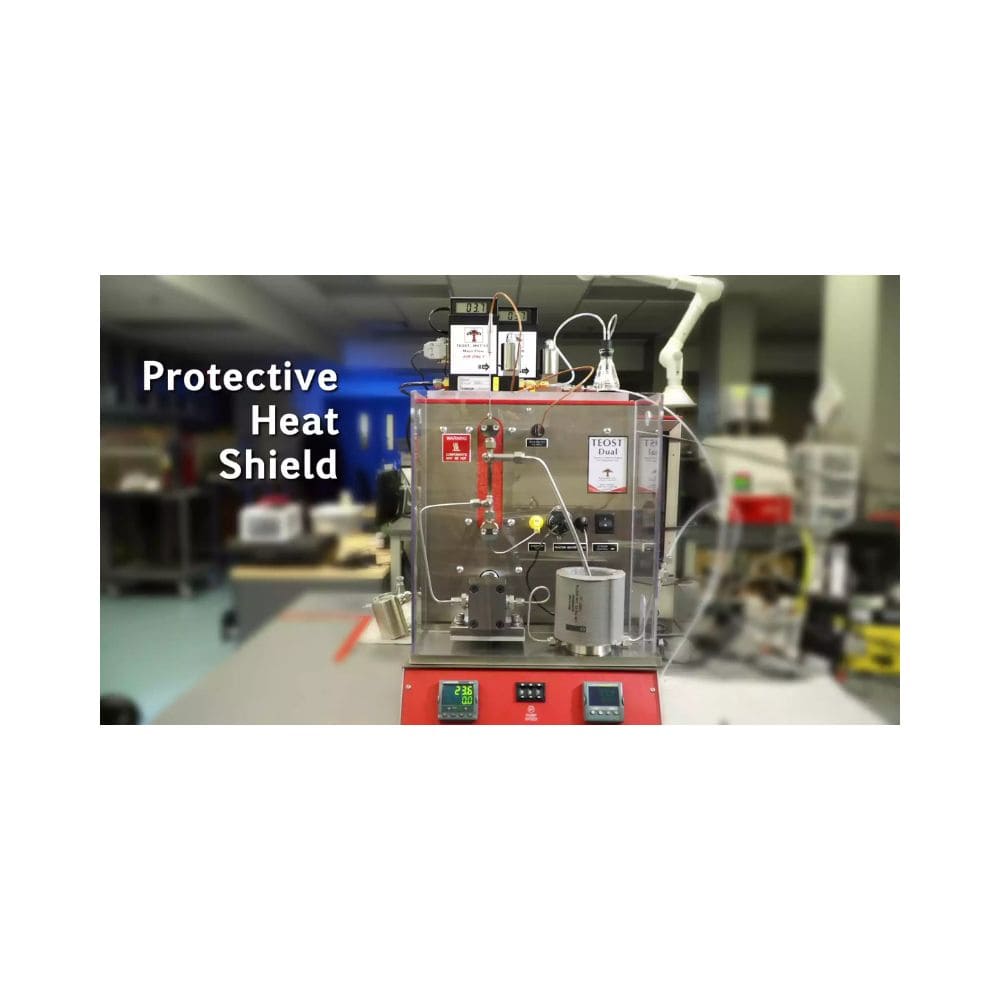

The TEOST® is a valuable tool for researchers, engineers, and quality control professionals seeking to understand and improve the performance of engine oils. It is a bench-top instrument designed to simulate engine operating conditions and assess the deposition tendencies of engine oils. It offers two primary testing protocols:

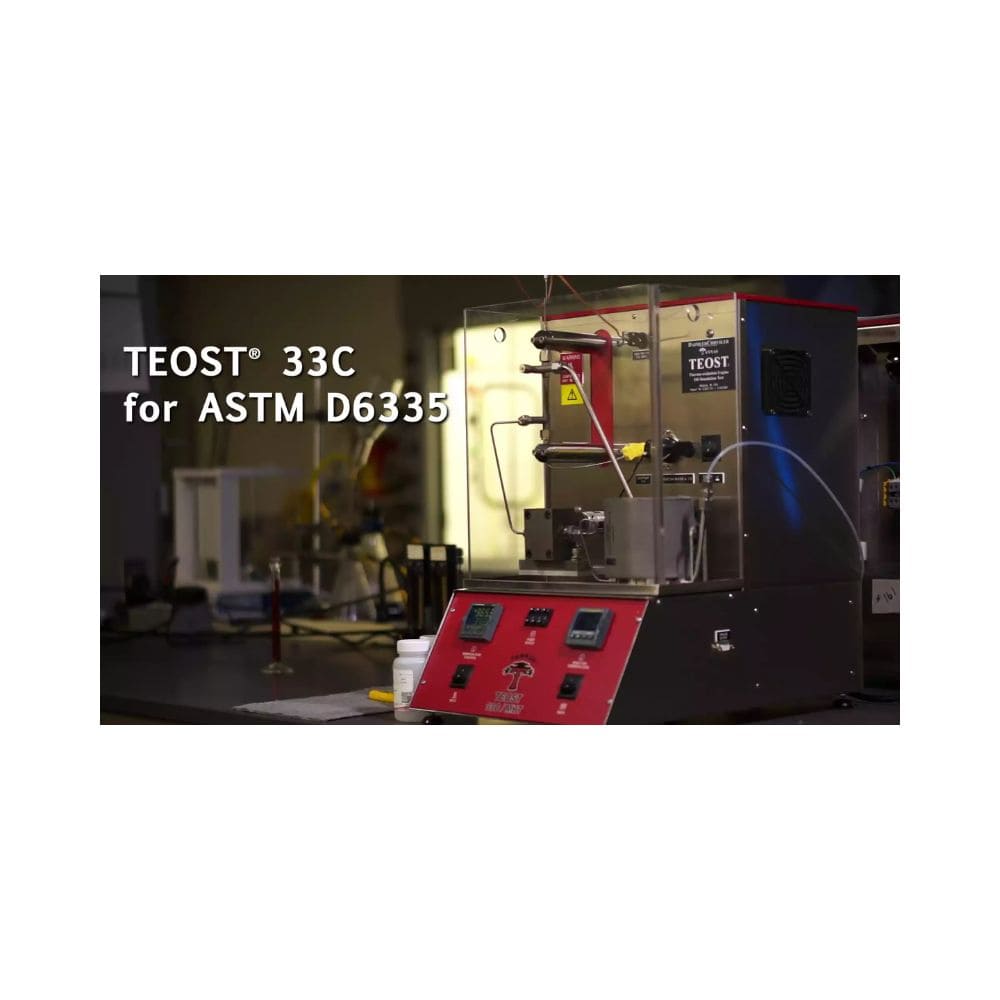

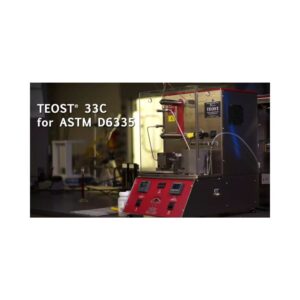

TEOST® 33C (ASTM D6335)

Simulates turbocharger operating conditions, including cyclic temperatures of 200-500°C. Measures oil deposition on a resistively-heated rod over a 12-cycle, 2-hour test. Used in ILSAC GF-2, API SJ, and Daimler/Chrysler OEM specifications.

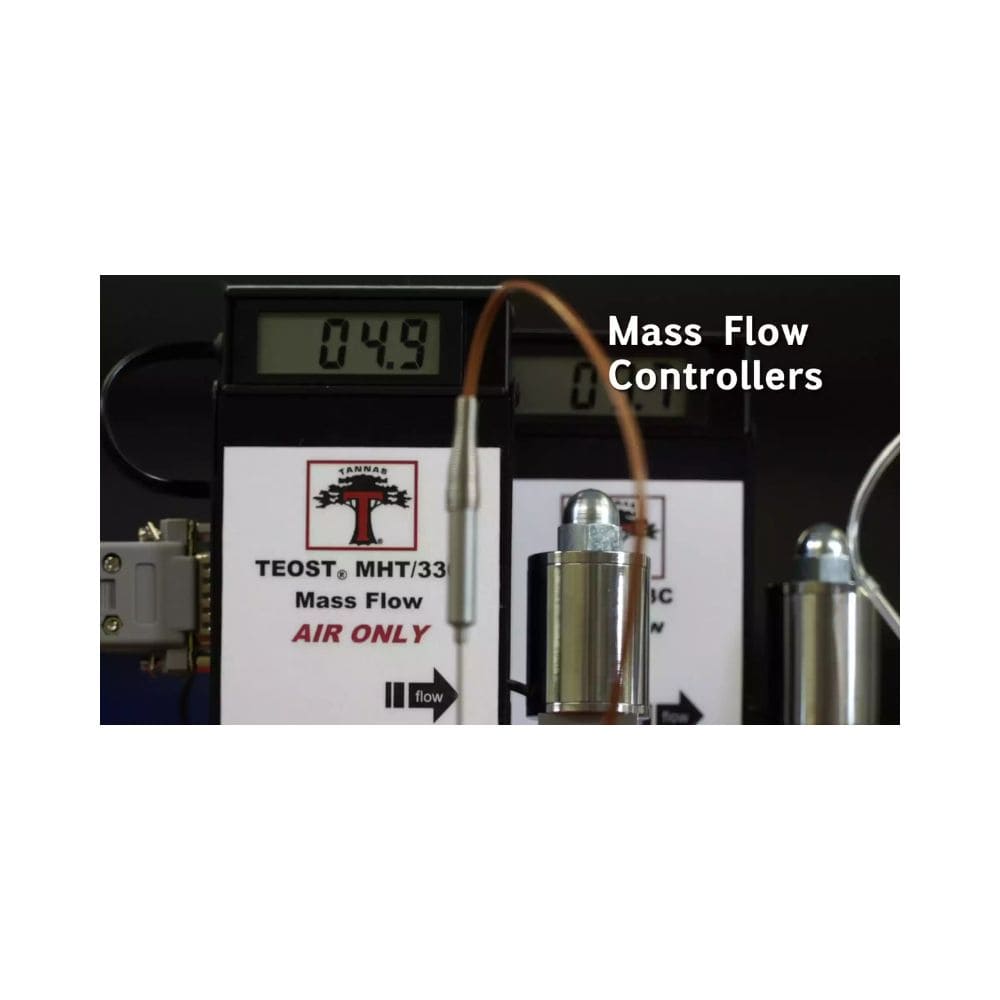

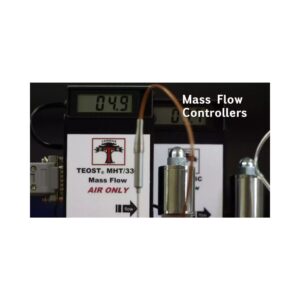

TEOST® MHT (ASTM D7097)

Simulates high-temperature conditions (250-300°C) in the piston ring belt area.

Measures oil deposition on a steel rod over a 24-hour test.

Used in ILSAC GF-3, GF-4, API SL, and SM categories.

Download Brochure

Description

Key Benefits

- Efficiency: Provides rapid and accurate assessment of engine oil deposition.

- Versatility: Offers two distinct testing protocols to address various engine operating conditions.

- Reliability: Adheres to industry standards, including ASTM D6335 and ASTM D7097.

- Cost-Effectiveness: A more efficient alternative to large-scale engine testing.

Applications

- Engine Oil Research and Development: Evaluating the performance of engine oils under different operating conditions.

- Quality Control: Ensuring the quality and performance of engine oils.

- Regulatory Compliance: Meeting industry standards and specifications.

Technical Specifications

- TEOST® 33C: 12-cycle test, 2-hour duration, 100+ mL sample volume, 0.45 g/minute oil flow rate

- TEOST® MHT: 24-hour test, 10 mL sample volume, 285°C test temperature

Additional Information

| Make | Tannas King |

|---|---|

| Method | ASTM D6335 | 33C, ASTM D7097 | MHT®, ASTM D8447 | TEOST Turbo®, Chinese SH/T0750 |