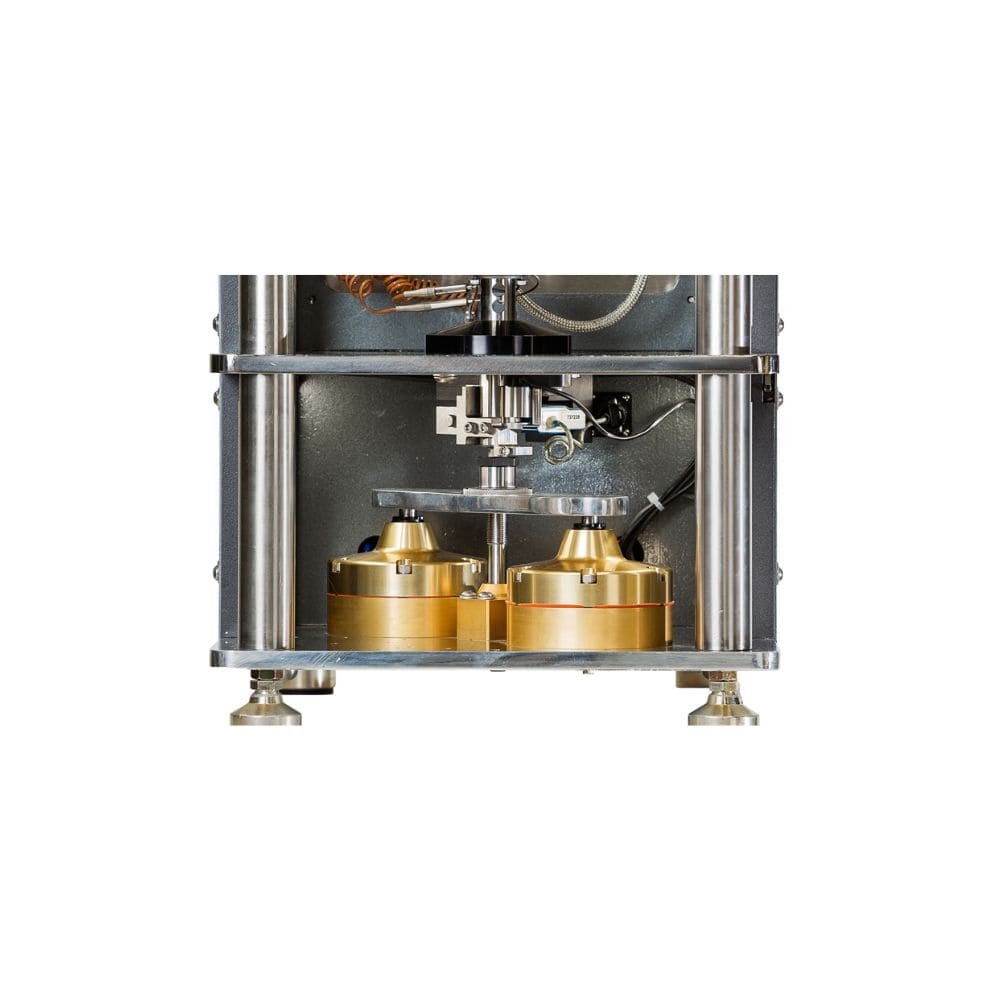

Multi Contact Tribolobical Tester

FALEX MCTT Multi-Contact Tribological Tester is a state-of-the-art tribological tester designed to evaluate the friction, wear, and abrasion characteristics of materials, coatings, and lubricants under a wide range of conditions. Its versatility and flexibility make it suitable for various applications, including research, development, quality control, and product qualification. It is a versatile and reliable tribological tester that offers precise and accurate measurements for a wide range of applications. Its advanced features and user-friendly interface make it an essential tool for research, development, and quality control.

Key Features

- Versatile Testing: Accommodates a variety of test geometries and conditions to simulate real-world applications.

- Comprehensive Analysis: Evaluates wear rates, PV limits, and static and dynamic coefficients of friction.

- Controlled Environment: Provides precise control over contact geometries, specimen materials, speed, pressures, and temperatures.

- ASTM Compliance: Adheres to ASTM standards for standardized testing.

- Wide Application Range: Suitable for testing polymers, lubricants, coatings, surface treatments, and dry films.

- Temperature Control: Offers a wide temperature range from ambient to 200°C with optional heating and cooling systems.

- Accurate Friction Measurement: Measures torque using a load cell and calculates real-time coefficient of friction.

- User-Friendly Interface: Provides easy control of test parameters and clear data display.

- Data Acquisition: Records and analyzes test data using the Falex SoftWEAR™ software.

Download Brochure

Description

Technical Specifications

- Drive System: Computer-controlled servo motor (equivalent to 2 Hp) with ± 0.5% accuracy

- Speed Range: 30-3600 RPM (standard), optional configurations for 15-1800 rpm and 60-3600 rpm

- Oscillatory Motion Control: Optional reversible drive for angles of motion from 5° to 720°Environments: Standard systems provide fluid and test specimen initial temperature set point (ambient to 150°C) using liquid or dry environments.

- Temperature Control: Automated test temperature system with computer control, user-defined parameters for ramping rates, soaking times, and test cycle control.

- Friction Measurement: Load cell for torque measurement, standard system includes a 0 to 100 lb. load cell.

- Utility Requirements: Power: 220 Volts, 60 cycle/50 cycle, single phase. Pneumatics: 80 psig (5.5 bar) clean, dry air required for pneumatic load systems.

- Space Requirements: Bench-top: 20 in. (L) x 28 in. (D) x 36 in. (H)

Additional Information

| Make | Falex |

|---|---|

| Method | ASTM D3702, ASTM G99 |