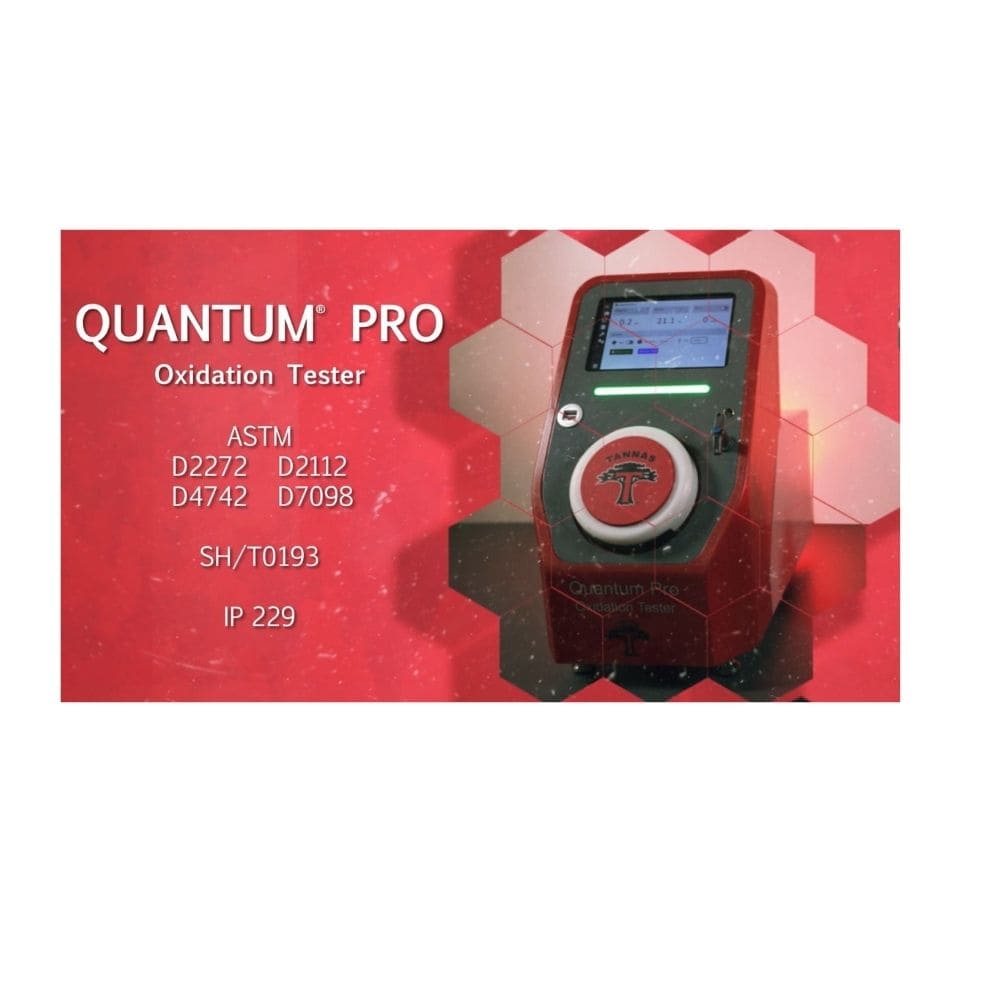

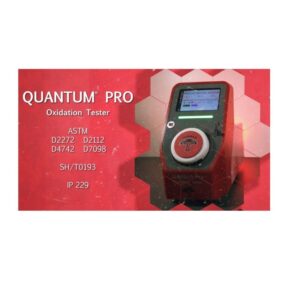

Tannas Oxidation Stability Tester – RPVOT

The Rotating Pressure Vessel Oxidation Test (RPVOT) is a crucial tool for assessing the oxidation stability of oils, providing a proactive approach to prevent premature degradation and equipment damage.

Key Features

- Proactive Monitoring: Detects potential oxidation problems before they lead to irreversible damage.

- Versatility: Suitable for large oil volumes and severe-duty applications.

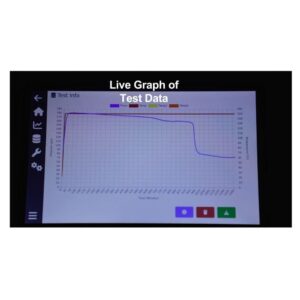

- Accuracy: Provides reliable and consistent results, adhering to ASTM D2112, D2272, and IP 229 standards.

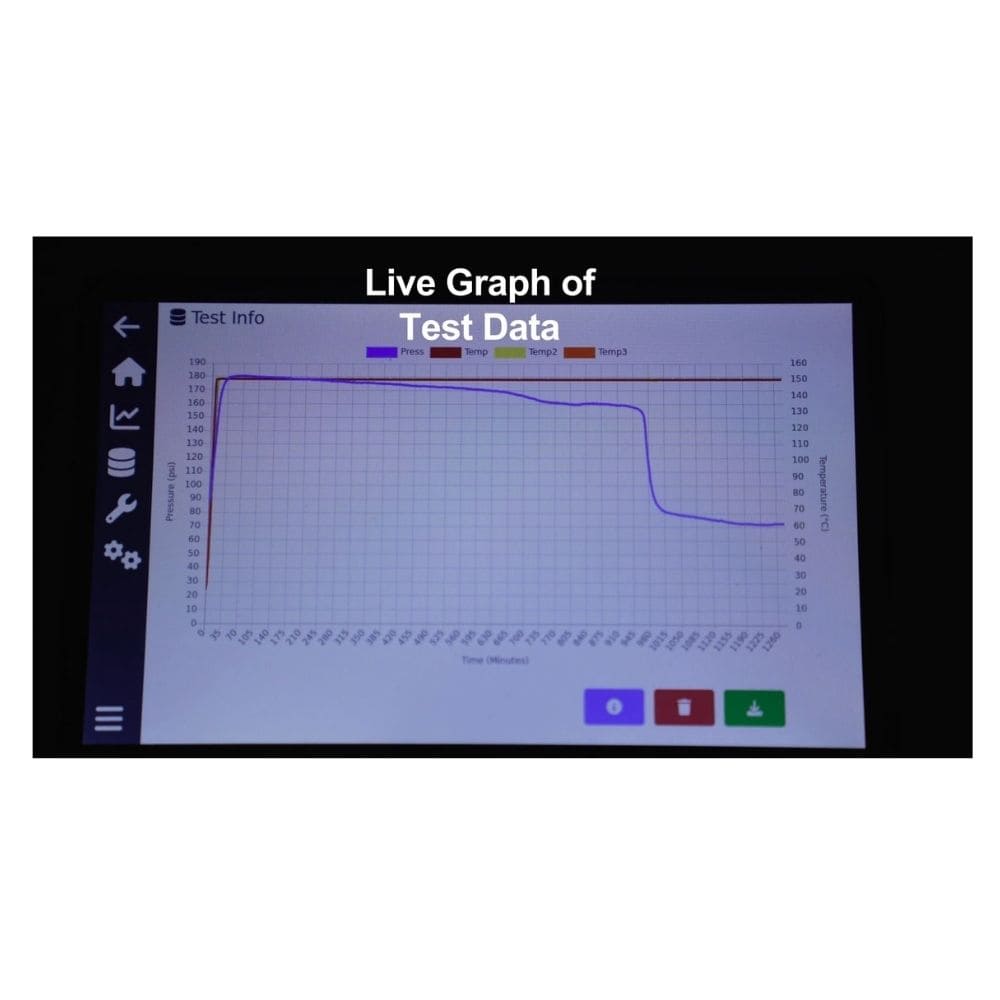

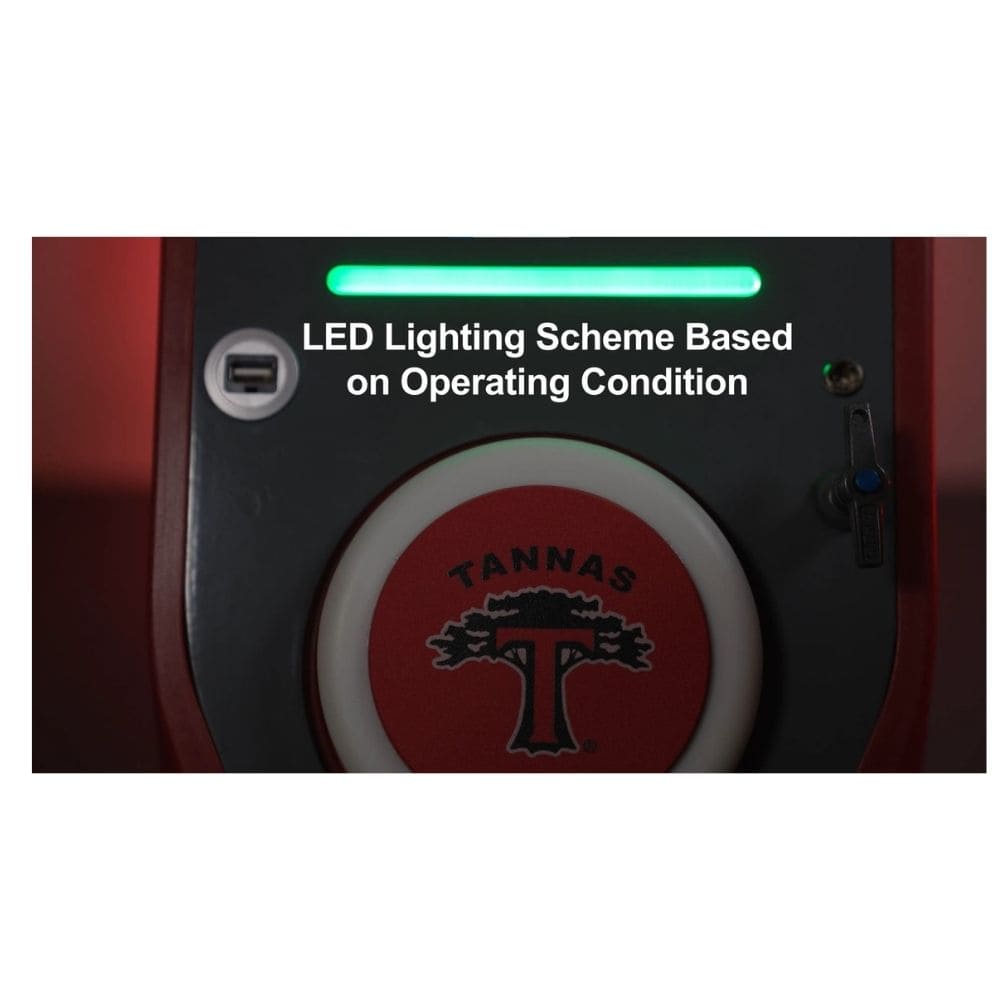

- Efficiency: Offers automated operation for streamlined testing processes.

- Applications:

- Steam Turbines: Monitoring the health of large oil reservoirs.

- Hydraulic Systems: Assessing the oxidation stability of hydraulic oils.

- Industrial Machinery: Preventing premature equipment failure due to oil degradation.

Download Brochure

Description

Technical Specifications

- Capacity: 2, 3, or 4 oxidation pressure vessels

- Temperature Control: Maximum Temperature: 200°C, Control Stability: ±0.02°C

- Heater Range: 0-2750W (2/3-vessel models), 0-3750W (4-vessel models)

- Recommended Bath Medium: High-temperature silicone heat transfer fluid

- Drive System: 100rpm positive drive transmission powered by a continuous duty 1/2hp ball bearing motor with built-in gear reducer

- Bath Capacity: K70200/K70290 (18 gal), K70300/K70390 (25 gal), K70400/K70490 (32 gal)

By incorporating RPVOT testing into your maintenance routine, you can proactively protect your equipment and extend its lifespan.

Additional Information

| Make | Tannas King |

|---|